W.C. Branham Inc. designs and manufactures custom cylinders and valves for your application. We have in-stock low-profile round or square cylinders. Our air cylinders feature light-duty stainless steel cylinders. Our customers include automation, material handling, printing industries, and others.

Vehicles – truck plus recreational and specialty vehicles – are our specialty. We produce products to keep these items running. One of the choices in our air products line is air cylinders. 2 1/2” and 3 1/2” stainless steel cylinders and fifth wheel air cylinders are in the offering.

Pneumatic Cylinders & Couplers is a manufacturer of NFPA tie rod aluminum and stainless steel cylinders, pneumatic cylinders as well as special designs to meet unique customer applications. Pneumatic Cylinders & Couplers products are used in the food processing, printing and packaging industries. Visit our website today to view our online catalogs for more information!

JIT Cylinders designs and manufactures NFPA tie-rod and custom industrial hydraulic and pneumatic cylinders. Bore sizes range from 5/16" to 30" and pressures up to 15,000 psi. With more than 100 years of manufacturing experience, we deliver consistent quality to meet your requirements.

More Air Cylinders Manufacturers

Air cylinders are a type of pneumatic actuator that convert compressed air energy into mechanical energy. The history of air cylinders can be traced back to the early 1900s, when pneumatic power started to become popular in industrial settings. The first pneumatic cylinders were simple devices that used compressed air to create linear motion. They were initially used in the mining industry to power drills and other equipment.

In the years that followed, air cylinders began to be used in other industries, including manufacturing, transportation, and agriculture. They were used to power conveyor systems, lift heavy loads, and control the motion of various types of machinery. In the 1920s, advances in materials and manufacturing techniques led to the development of more efficient and versatile air cylinders. These cylinders were used in a wider range of applications, and their popularity continued to grow throughout the 20th century. Today, air cylinders are used in a wide range of industries and applications, from aerospace and robotics to medical devices and transportation systems.

Components of Air Cylinders

Air cylinders consist of several essential components that work together to convert compressed air energy into mechanical motion. The cylinder barrel serves as the main body of the cylinder, enclosing the other components. It provides a guide for the piston to move back and forth smoothly. The piston is a crucial part of the cylinder, typically made of metal or elastomer, that converts the energy of the compressed air into mechanical force. It moves within the cylinder barrel, creating the desired linear or rotary motion. The end caps seal the cylinder barrel, ensuring proper containment of the compressed air and creating a controlled environment for the piston. They also house the ports through which the compressed air enters and exits the cylinder. Seals, such as O-rings or lip seals, are critical for maintaining air-tightness and preventing leakage. They help to maintain the lubrication of the piston and barrel, ensuring smooth movement and reducing wear. Ports are openings in the end caps that allow compressed air to flow in and out of the cylinder, enabling the desired motion. Finally, cushions are often used to absorb shock and minimize the impact noise that occurs when the piston reaches the end of its stroke. These components work in tandem to ensure the efficient and reliable operation of air cylinders in a wide range of applications.

Types of Air Cylinders

Air cylinders come in various types, each designed to suit specific applications and provide different modes of operation. Single-acting cylinders are one of the most common types, utilizing air pressure to move the piston in one direction, while a spring or other external force returns it to the original position. On the other hand, double-acting cylinders use air pressure to move the piston in both directions, offering more control over the motion and enabling applications that require pushing and pulling forces. Rodless cylinders are designed without a traditional piston rod extending from the cylinder body, instead utilizing a carriage or magnet to transfer the motion along the length of the cylinder. Rotary actuators, as the name suggests, convert air pressure into rotational motion, enabling precise control for tasks like turning valves or rotating objects. Compact cylinders are smaller in size and offer a space-saving solution for applications with limited space or where lightweight components are required. By understanding the different types of air cylinders available, it becomes possible to choose the most suitable type that matches the specific requirements of the application, whether it involves linear or rotary motion, single or double action, or the need for compactness and space efficiency.

Limitations of Air Cylinders

While air cylinders are a useful tool for many applications, they do have some limitations. Contamination is a common issue, as dust, dirt, and other particles can damage the seals and cause leakage. Temperature sensitivity is another issue, as extreme temperatures can affect the performance of the cylinder. Finally, air cylinders have limited speed control, which can make them unsuitable for certain applications.

Benefits of Air Cylinders

Despite their limitations, air cylinders offer several benefits. They are low maintenance and have a long lifespan, making them a cost-effective choice for many applications. They also provide high force output which makes them suitable for heavy-duty tasks. In addition, air cylinders are easy to install and operate, making them a popular choice in many industries.

Applications of Air Cylinders

Air cylinders are used in a wide range of applications across various industries. We elaborate on many of their applications below.

Manufacturing

Air cylinders are commonly used in manufacturing applications to control the motion of various types of machinery. They are often used in assembly lines, conveyor systems, and packaging machinery to automate the process and improve efficiency. For example, air cylinders can be used to move products down a conveyor belt, push components into place during assembly, or lift heavy loads for packaging.

Transportation

Air cylinders are used in various transportation systems, including braking systems, suspension systems, and door opening mechanisms. In commercial vehicles such as buses and trucks, air cylinders are used to power the braking system, which helps to stop the vehicle quickly and safely. In trains, air cylinders are used to control the suspension system and absorb shocks from the track. They are also used to open and close doors in trains, buses, and other vehicles.

Aerospace

Air cylinders play a critical role in the aerospace industry, where they are used in landing gear, wing flaps, and engine thrust reversers. In aircraft landing gear, air cylinders are used to retract and extend the landing gear. They are also used in wing flaps to adjust the angle of the wings during takeoff and landing. In engine thrust reversers, air cylinders are used to move the deflector plates that redirect the engine’s thrust, which helps to slow the aircraft down during landing.

Medical

Air cylinders are used in various medical devices, including respirators and prosthetic limbs. In respirators, air cylinders are used to power the device and deliver oxygen to patients with respiratory problems. In prosthetic limbs, air cylinders are used to control the movement of the limb and help the user perform everyday tasks.

Robotics

Air cylinders are commonly used in robotics to control the motion of robotic arms and grippers. They are often used in manufacturing settings to automate processes and improve efficiency. For example, air cylinders can be used to control the movement of a robotic arm as it picks up and places components during assembly.

Mining

As mentioned earlier, air cylinders were initially used in the mining industry to power drills and other equipment. Today, they continue to be used in mining applications to power conveyor systems, lift heavy loads, and control the movement of equipment.

Construction

Air cylinders are used in various construction applications, including heavy equipment such as bulldozers and excavators. They are often used to control the movement of the equipment and lift heavy loads.

The Future of Air Cylinders

The future of air cylinders holds potential for further advancements and innovations in their design and capabilities. With ongoing developments in materials, manufacturing techniques, and automation technologies, we can expect improvements in the efficiency, performance, and versatility of air cylinders. Efforts may focus on enhancing the sealing mechanisms to minimize leakage and improve overall reliability. Research and development may also lead to the development of more lightweight and compact air cylinder designs, allowing for increased integration options in various applications, particularly where space is limited. Additionally, advancements in sensor technology and connectivity could enable the integration of smart features into air cylinders, facilitating real-time monitoring, predictive maintenance, and enhanced control. As industries continue to evolve and demand greater precision, speed, and energy efficiency, air cylinders are likely to adapt and evolve alongside these needs, opening up new possibilities and applications across a wide range of industries, such as robotics, automation, healthcare, and beyond. The future of air cylinders is promising, and it is anticipated that they will continue to play a significant role in powering pneumatic systems and delivering reliable mechanical motion.

Choosing the Right Air Cylinder Manufacturer

To ensure you have the most constructive outcome when purchasing air cylinders from an air cylinder manufacturer, it is important to compare several companies using our directory of air cylinder manufacturers. Each air cylinder manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to communicate with the manufacturer for more information or request a quote. Review each air cylinder business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple air cylinder companies with the same form.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

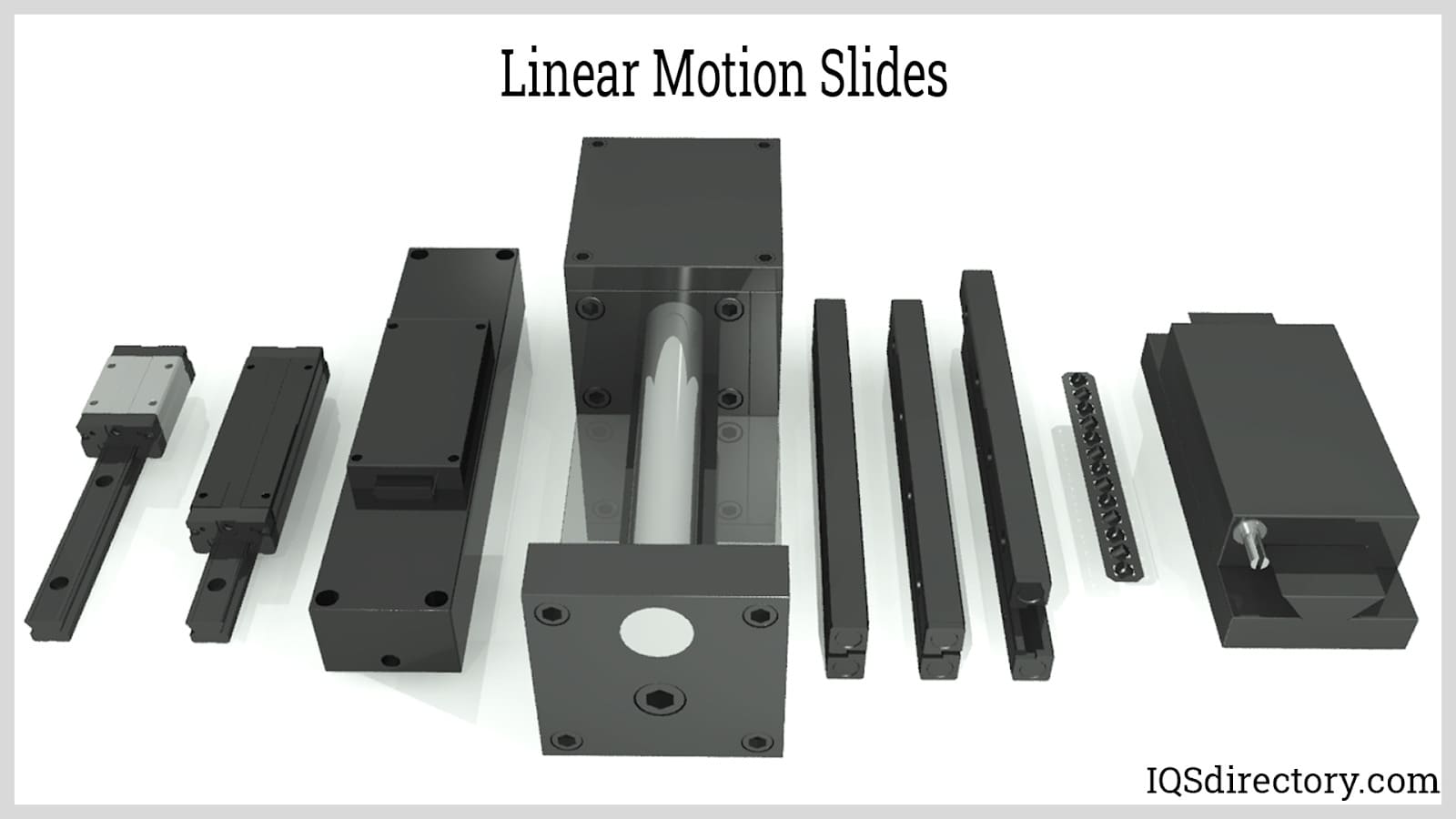

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services