W.C. Branham Inc. designs and manufactures custom cylinders and valves for your application. We have in-stock low-profile round or square cylinders. Our air cylinders feature light-duty stainless steel cylinders. Our customers include automation, material handling, printing industries, and others.

Vehicles – truck plus recreational and specialty vehicles – are our specialty. We produce products to keep these items running. One of the choices in our air products line is air cylinders. 2 1/2” and 3 1/2” stainless steel cylinders and fifth wheel air cylinders are in the offering.

Pneumatic Cylinders & Couplers is a manufacturer of NFPA tie rod aluminum and stainless steel cylinders, pneumatic cylinders as well as special designs to meet unique customer applications. Pneumatic Cylinders & Couplers products are used in the food processing, printing and packaging industries. Visit our website today to view our online catalogs for more information!

JIT Cylinders designs and manufactures NFPA tie-rod and custom industrial hydraulic and pneumatic cylinders. Bore sizes range from 5/16" to 30" and pressures up to 15,000 psi. With more than 100 years of manufacturing experience, we deliver consistent quality to meet your requirements.

More Small Air Cylinder Manufacturers

Small air cylinders are compact pneumatic actuators precision-built to maximize productivity within a limited amount of space. As with all air cylinders, these mechanisms utilize pressure differentials in order to convert compressed air energy into mechanical energy. This linear energy is used in a number of industrial and commercial applications.

Though often much smaller than traditional industrial air cylinders, these alternative models offer significant space savings, often with little to no reduction in capability. Linear and rotary cylinders are frequently used in machine loading, material handling, product assembly, welding, packing and clamping processes among others. Small air cylinders continue to expand the capabilities of linear actuators allowing for the easy integration and incorporation of units in pre-existing workspaces where space is at a premium.

Compact models are often as much as 60% smaller than comparable traditional cylinders. For this reason automotive, building, construction, electronics, food processing and packaging, metal working, mining, construction, textile and forestry industries use these air powered devices as actuators for valves, lift gates, and machine and engine components.

Because small air cylinders use only compressed air, they offer an economic and environmentally friendly solution to many mechanical operations. Unlike larger air cylinders, however, repairs can be difficult on styles that can be as small as 7/16", making disposable small cylinders common, adding to cost and environmental impact.

The size, large or small, of an air cylinder is measured in several ways, such as diameter and length. The stroke, however, is often the most important measurement. This is the distance between fully extended and fully retracted piston positions. As many air cylinder systems rely on piston rods, the stroke length is often double that of the cylinder itself. In order to reduce size without sacrificing productivity and functionality, many smaller models are in fact rodless cylinders, though miniaturized piston rod options are also available.

The most common alternatives to small rod models are rack and pinion or cable cylinders. The basic construction of each type of small air cylinder is fairly similar. Precision machined aluminum, steel or stainless steel components include a circular or rectangular cylinder with an air valve for inlet and exhaust located at one or both ends. Single acting or unidirectional cylinders have one inlet, while double acting cylinders, which provide powered motion in two directions, have two valves.

No matter the directional capabilities, one or more pistons are located within the shaft. The piston is attached to a cable, rack or rod. When compressed air flows into the enclosed shaft, it acts upon the piston face, which moves the secondary implement creating linear motion. This motion is transferred to the tooling or load being handled in a specific application. As manufacturers offer a number of designs and styles it is important to carefully compare small air cylinder capabilities to the requirements of the industrial process at hand.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

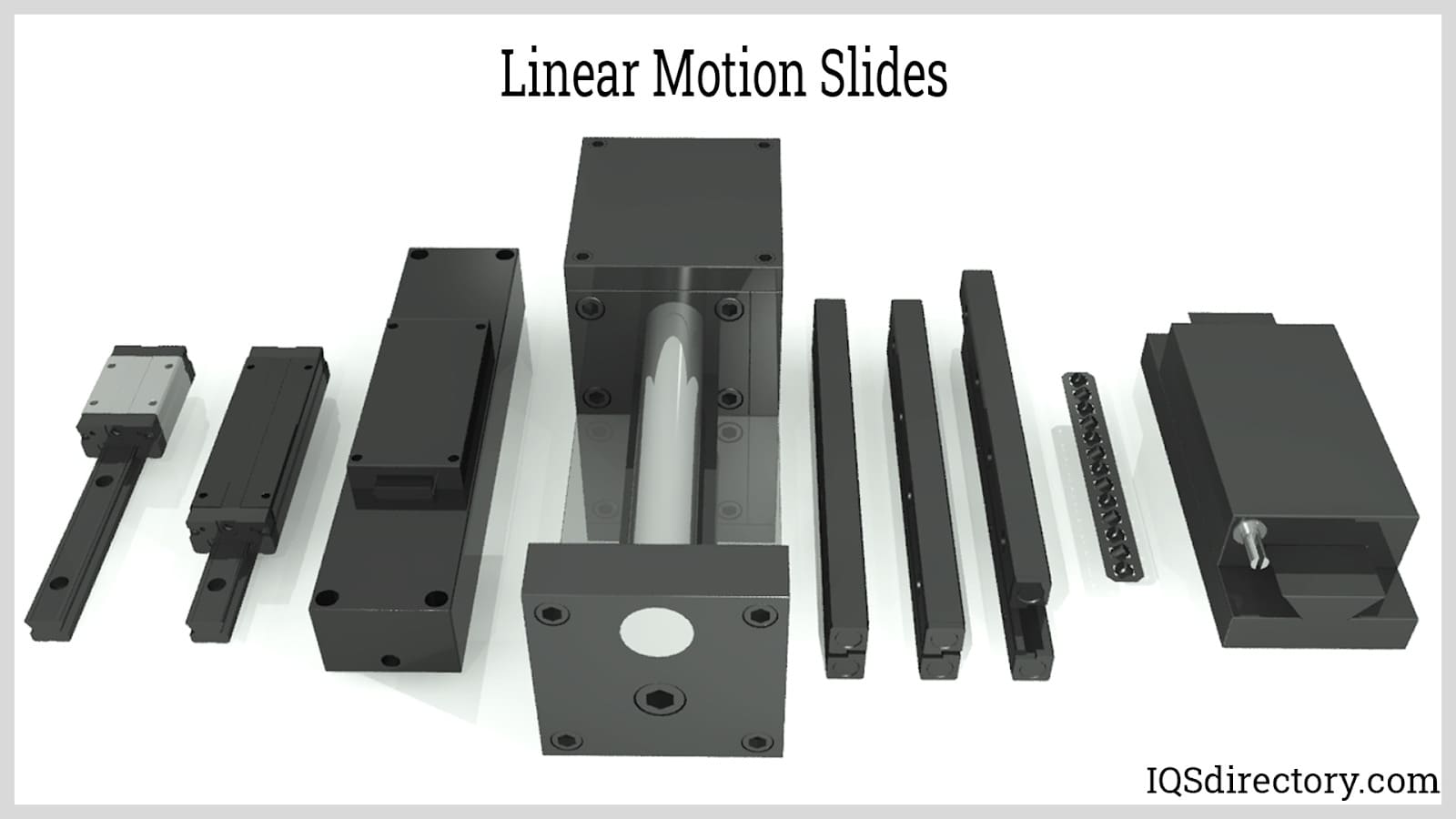

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services