W.C. Branham Inc. designs and manufactures custom cylinders and valves for your application. We have in-stock low-profile round or square cylinders. Our air cylinders feature light-duty stainless steel cylinders. Our customers include automation, material handling, printing industries, and others.

Vehicles – truck plus recreational and specialty vehicles – are our specialty. We produce products to keep these items running. One of the choices in our air products line is air cylinders. 2 1/2” and 3 1/2” stainless steel cylinders and fifth wheel air cylinders are in the offering.

Pneumatic Cylinders & Couplers is a manufacturer of NFPA tie rod aluminum and stainless steel cylinders, pneumatic cylinders as well as special designs to meet unique customer applications. Pneumatic Cylinders & Couplers products are used in the food processing, printing and packaging industries. Visit our website today to view our online catalogs for more information!

JIT Cylinders designs and manufactures NFPA tie-rod and custom industrial hydraulic and pneumatic cylinders. Bore sizes range from 5/16" to 30" and pressures up to 15,000 psi. With more than 100 years of manufacturing experience, we deliver consistent quality to meet your requirements.

More Compressed Air Cylinder Manufacturers

Compressed air cylinders are pneumatic tools that move objects through the power of compressed air. Air cylinders are employed for numerous reasons in a wide range of settings. These cylinders can be used to open and close big doors. Is it any wonder that they are vital components of most businesses and industries? Below are just a few industries for you to consider benefitting from air cylinders and their various applications.

They serve as components of various machinery and enable the movement of other objects. For example, they are a component of the air brake systems on large trucks.

- Automotive production

- Supply industries

- Food processing

- Electronics

- Mining

- Packaging

Compressed air cylinders transform the potential energy of compressed gasses into mechanical energy. A cylinder, a piston, and at least one inlet are the components of an air cylinder. The piston is propelled to move when compressed air is introduced into the cylinder through the inlet. Valves manage the flow of compressed air into the cylinder.

Air cylinders can be set up in various ways, and how they are set up depends on how they are used. The most basic and prevalent cylinder types are those with a standard rod attachment. They can have a diameter of up to 1000 mm or, in the case of tiny air cylinders, a diameter as little as 2.5 mm. Cylinders with rods can move laterally, but other air cylinders (double-acting cylinder) can also move in both directions. Rotary air cylinders, meanwhile, move objects in a circular pattern.

Types of Compressed Air Cylinders and How They Operate

The two most common types of compressed air cylinders are single-acting and double-acting compressed air cylinders.

- A single-acting cylinder can only move in one direction when functioning. A single-acting air cylinder uses a spring to provide the return force once the air pressure is released, and air pressure is applied to one side of the piston flange to provide force and motion. For a single operational cycle, single-acting cylinders need about half the air that double-acting cylinders do.

- Double-acting cylinders are the most popular pneumatic because they provide total operator control over the piston movement. A double-acting compressed pneumatic cylinderhas pressure on both sides and propels motion in two directions. Compressed air forces these cylinders to travel backward when pushed outward in one direction. The pressurized air is supplied into the cylinder using lines that enter both ends—the piston and piston rod move when pressurized air enters the cap-end port and the rod-end port. When the piston rod is retracted, it is in a negative position, and when it is extended, it is in a favorable position. The piston is propelled forward or positively when compressed air enters the cap-end port, lengthening the piston rod. The rod-end port is then forced to release air, and compressed air enters the rod-end port to retract the piston rod, forcing air out of the cap-end port to retract the piston to the negative position. Double-acting cylinders provide a variety of benefits over single-acting cylinders. They are more powerful and efficient and require less energy to perform most tasks. However, suppose the application calls for a base position during fail-safe situations in the event of compressed air loss. In that case, a double-acting cylinder shouldn't be employed since they use more energy than compressed air in both directions.

Advantages of Compressed Air Cylinders

As we have discussed, compressed air cylinders provide an excellent source of useful energy. Here, we consider some additional benefits they provide.

- They are a light source of energy.

- Compressed air cylinders are adaptable to many applications and environmental conditions.

- They move objects in various directions.

- They have many mounting options to ensure maximum performance further.

- Many standard configurations are possible.

- Devices can customize compressed air systems individually or as part of a system to offer virtually unlimited options for mechanical energy.

- Compressed air provides a source of cheap and green energy.

- Feedback sensors can be applied to accommodate multiple load positions.

Drawbacks of Compressed Air Cylinders

As we have seen, compressed air cylinders provide an excellent source of mechanical energy. But, sadly, as we know, there is no perfect energy source. Here, we examine some of the limitations of compressed air cylinders.

- Single-acting compact cylinders do not deliver a constant output force across the entire length of the piston stroke because of the opposing spring force. Additionally, the compressed spring's space limits the stroke of single-acting cylinders.

- Compressed air cylinders can be dangerous in limited situations; if a valve cap breaks or is compromised, the cylinder can go flying and cause potential damage or injury.

- Since air is compressible, the load can readily alter the cylinder's operating speed.

- Frictional force significantly impacts their thrust when moving at low speeds, thus reducing performance.

Choosing the Right Compressed Air Cylinders Company

To make sure you have the most positive outcome when purchasing Compressed Air Cylinders from a Compressed Air Cylinders Manufacturer, it is important to compare at least 4 or 5 Companies using our list of Compressed Air Cylinders manufacturers. Each Compressed Air Cylinders Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Compressed Air Cylinders company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Compressed Air Cylinders companies with the same message.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

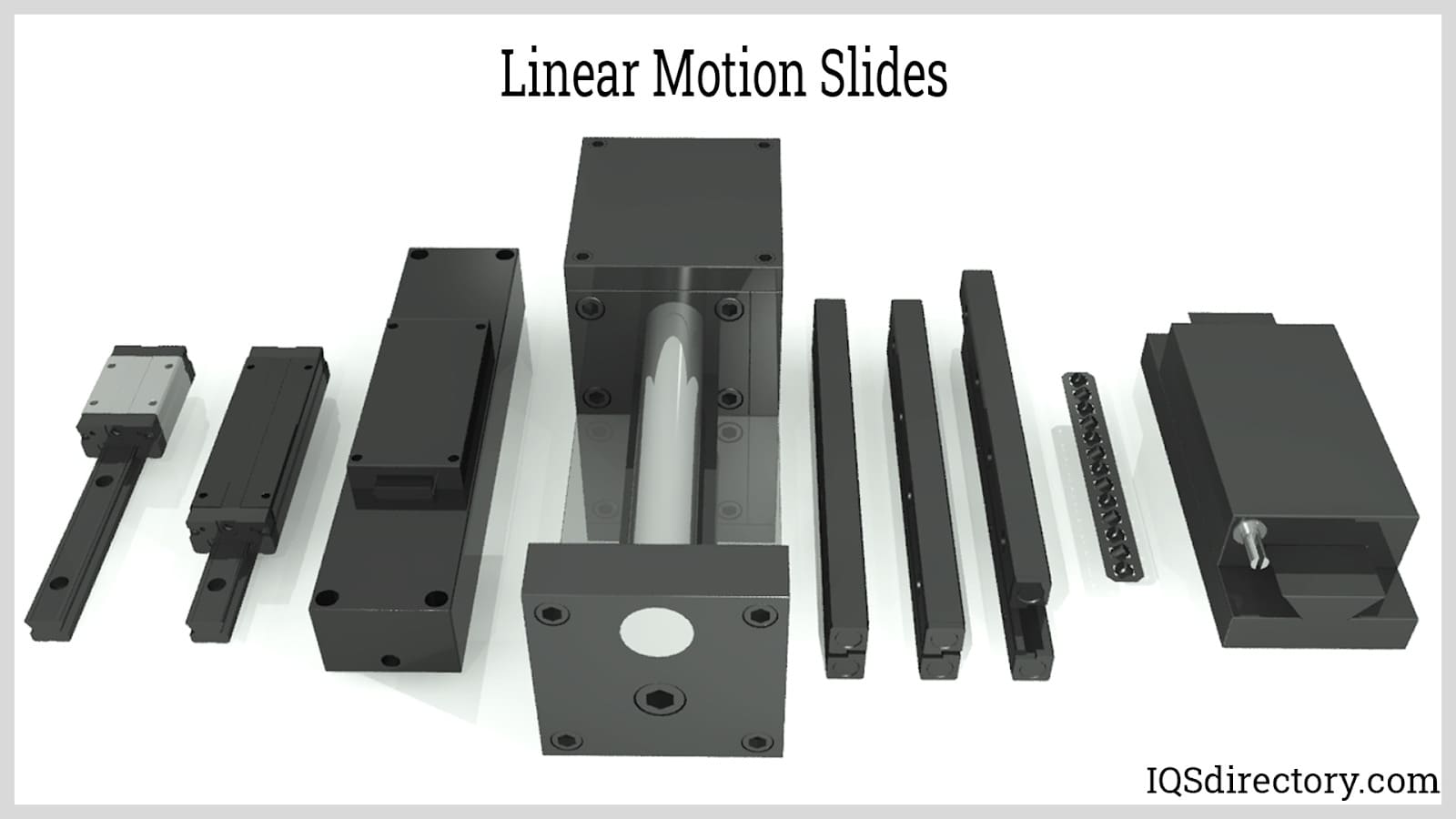

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services