W.C. Branham Inc. designs and manufactures custom cylinders and valves for your application. We have in-stock low-profile round or square cylinders. Our air cylinders feature light-duty stainless steel cylinders. Our customers include automation, material handling, printing industries, and others.

Vehicles – truck plus recreational and specialty vehicles – are our specialty. We produce products to keep these items running. One of the choices in our air products line is air cylinders. 2 1/2” and 3 1/2” stainless steel cylinders and fifth wheel air cylinders are in the offering.

Pneumatic Cylinders & Couplers is a manufacturer of NFPA tie rod aluminum and stainless steel cylinders, pneumatic cylinders as well as special designs to meet unique customer applications. Pneumatic Cylinders & Couplers products are used in the food processing, printing and packaging industries. Visit our website today to view our online catalogs for more information!

JIT Cylinders designs and manufactures NFPA tie-rod and custom industrial hydraulic and pneumatic cylinders. Bore sizes range from 5/16" to 30" and pressures up to 15,000 psi. With more than 100 years of manufacturing experience, we deliver consistent quality to meet your requirements.

More Compact Air Cylinder Manufacturers

Compact air cylinders are pneumatic cylinders with an installation length that is extremely compact in relation to stroke length. They are used when space is extremely limited and the requirements for lateral loads are low.

These compact, round-body cylinders, often known as pancake cylinders, are excellent for applications requiring strong force and a short stroke within a limited space. The bore of a typical compact air cylinder ranges in size from 12mm (0.472441”) to 100mm (3.93701”) with standard size ranging from 1.5mm (0.0590551) to 100mm. With the typical maximum stroke of 100mm, these cylinders are also frequently referenced as short- stroke cylinders.

Compact air cylinders are chosen based on how well they can carry out a certain task. There are different designs, choices, and combinations offered by numerous manufacturers. Occasionally, however, the task at hand cannot be completed with a normal product and a custom product is required. Custom tiny air actuator development is frequently time- and money -consuming but may be the only option for particular applications.

Types of Compact Air Cylinders

There are two types of compact air cylinders and these are single-acting and double-acting cylinders.

Single-Acting Cylinders

- Single-acting (or single-rod) cylinders have compressed air (or another working fluid) supplied to only one side of the piston and the other side vents the air outward. The rod (the metal bar that transmits the force of the piston to the machine) expands or retracts depending on whether air is present within. The rod is spring-extended while the cylinder is full of air. A typical single-acting cylinder is pressure-extended, where, when air is exhausted, an internal spring returns the piston to its initial position; this is typically called spring return. Single-acting cylinders are the best choice when a force is required just in one direction and where the return stroke is unhindered and unloaded since the spring force causes the rod to lengthen. These devices are also common in locations where, for safety reasons, a defined position must be taken in the event of a power failure.

Double-Acting Cylinders

- A double-acting cylinder acts with compressed air (or other fluid) alternating between both sides of the piston. A double-acting cylinder can perform work on both sides when the operating fluid is properly balanced and displaced on both sides of the piston. Double-rod cylinders are used when It is mechanically advantageous to couple a load to each end, or when the extra end can be utilized to install cams for controlling limit switches.

Applications of Compact Air Cylinders

Although compact air cylinders are smaller than other types of cylinders they can, nonetheless, be just as powerful. They have a wide range of uses for linear actuation and control, such as:

- Single-acting compact cylinders are used in processes like transporting material-handling equipment to printing presses.

- In many food-processing situations, a typical cylinder might not fit due to a lack of room. Or, a space may be difficult to accommodate a regular cylinder due to its design and, even if it does fit, it is difficult to get the most out of the cylinder, resulting in lower productivity and, eventually, lower profitability. For food processors, the ability to minimize their operational footprint without compromising power, efficiency, or control can significantly affect their bottom line. Compact cylinders are perfect for lighter-duty applications because they can fit in tight locations and support movements that only need a brief stroke because the rod moves on a tiny bearing surface.

- Double-acting compact cylinders are commonly used in assembling, clamping, and other movement/positioning applications.

- Filling and bottling industries also make use of compact cylinders since they fit in areas with less space.

- Animatronic decorations typically feature compact cylinders to provide character movement.

Benefits of Using Compact Air Cylinders

- Compact air cylinders offer high performance at low prices.

- They are easily adapted to a wide range of machines and environments.

- Some compact air cylinders feature a special oval bore cylinder which solves the problem of eccentric loads which cause premature or uneven wear of seals and bearings. Additionally, since these cylinders have an oval shape it means the rod cannot rotate when extended. This results in a lower risk of component damage, higher durability, a higher period of reliable use and, ultimately, increased savings as a result of increased productivity.

- They require less installation space.

- They require less time and labor to install.

Choosing the Right Compact Air Cylinders Manufacturer

To make sure you have the most beneficial outcome by purchasing Compact Air Cylinders from a Compact Air Cylinders company, it is important to compare at least 4 or 5 manufacturers using our list of Compact Air Cylinders companies. Each Compact Air Cylinders supplier has a business profile page which highlights their areas of experience and capabilities, and has a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Compact Air Cylinders business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Compact Air Cylinders businesses with the same quote.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

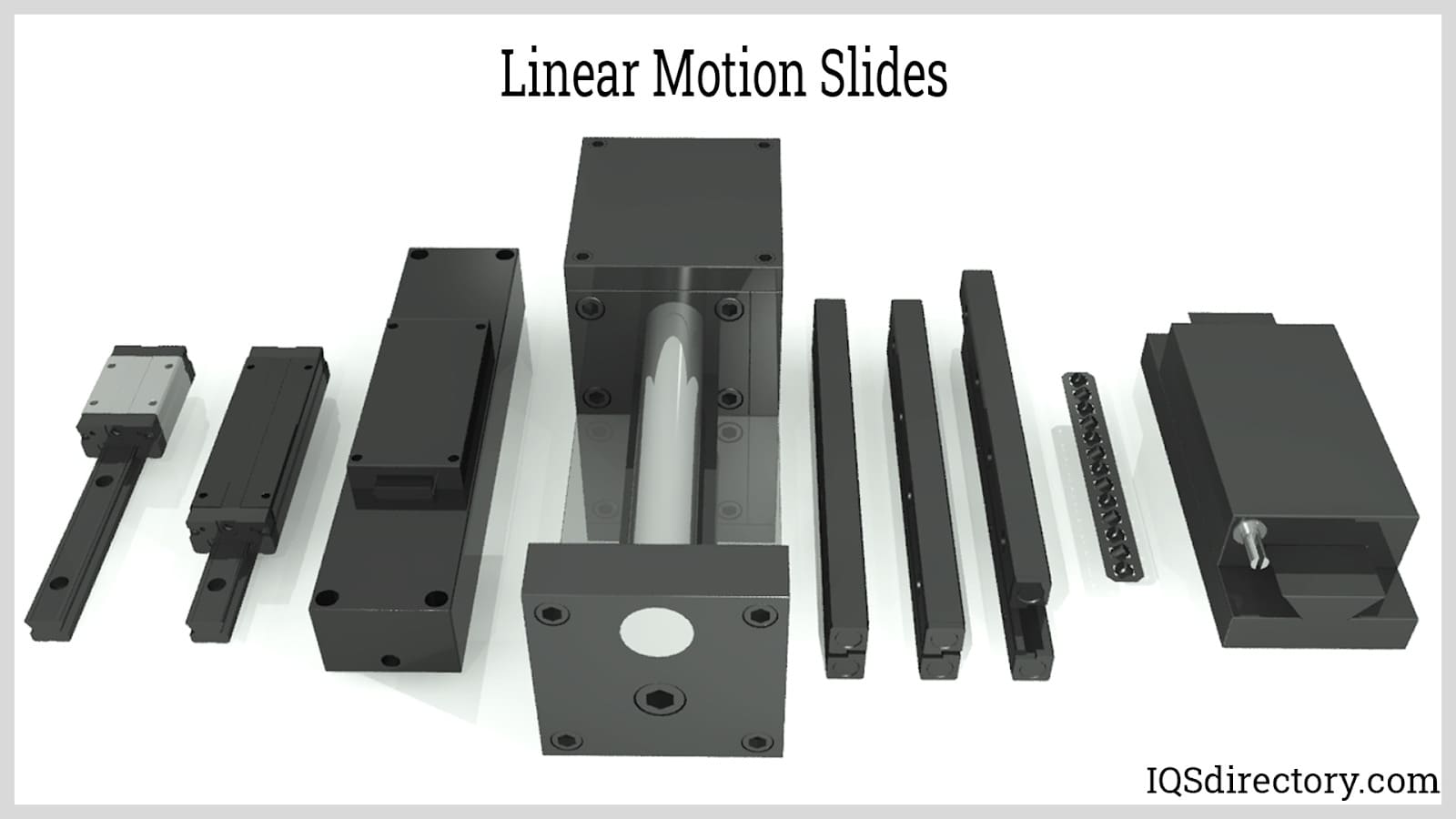

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services