W.C. Branham Inc. designs and manufactures custom cylinders and valves for your application. We have in-stock low-profile round or square cylinders. Our air cylinders feature light-duty stainless steel cylinders. Our customers include automation, material handling, printing industries, and others.

Vehicles – truck plus recreational and specialty vehicles – are our specialty. We produce products to keep these items running. One of the choices in our air products line is air cylinders. 2 1/2” and 3 1/2” stainless steel cylinders and fifth wheel air cylinders are in the offering.

Pneumatic Cylinders & Couplers is a manufacturer of NFPA tie rod aluminum and stainless steel cylinders, pneumatic cylinders as well as special designs to meet unique customer applications. Pneumatic Cylinders & Couplers products are used in the food processing, printing and packaging industries. Visit our website today to view our online catalogs for more information!

JIT Cylinders designs and manufactures NFPA tie-rod and custom industrial hydraulic and pneumatic cylinders. Bore sizes range from 5/16" to 30" and pressures up to 15,000 psi. With more than 100 years of manufacturing experience, we deliver consistent quality to meet your requirements.

More Pneumatic Cylinder Manufacturers

Mechanical pneumatic cylinders use the energy from pressured air to generate force. These gadgets consist of a cylinder, piston, and piston rod. The pressure increases as air enters the cylinder from one side. The piston moves in a certain direction due to increased internal pressure. The produced force is transferred to the item to be pushed by the piston rod.

Like hydraulic cylinders, an external force propels pistons in the intended direction. The piston, a cylinder or disk, transmits the force it generates to the object that has to be pushed through the piston rod. Since pneumatics require less room for fluid storage and are quieter, cleaner, and more efficient, engineers occasionally prefer to utilize them. In addition, pneumatics are preferable where cleanliness is required because a leak from this device (pneumatic cylinder) will not seep out and pollute the surroundings. After all, the working fluid is a gas.

Types of Pneumatic Cylinders

Double-Acting Pneumatic Cylinders

Compressed air can be supplied into double-acting cylinders on either side of the piston. The rod and piston assembly will slide to that side when there is reduced internal pressure in the chamber. As a result, the piston and rod system can make both extended and retraction strokes. By delivering compressed air on the opposite side of the cylinder, the rod and piston assembly reset to its initial position. Because there is more surface area on the side of the piston close to the rear-end cap, the expansion forces of the double-acting cylinders are larger than the retraction force. This process is only true when equal pressure is given to each piston's side.

Additionally, the rod's reduced effective volume causes the chamber to fill with compressed air more quickly, making the retraction speed quicker than the extension speed. Double-acting cylinders help open and close gates and valves. They are employed in situations when considerable force and speed are necessary. They also have longer strokes and a stronger, steadier output force. Consequently, they need a more powerful cushioning system. Since pressurized air pushes the rod and piston assembly in both directions, it moves more quickly and precisely. Double-acting cylinders cost more and require more compressed air to operate. In the instance of a sudden pressure failure, the piston's location cannot be established.

Single-Acting Pneumatic Cylinders

Some springs are positioned around the piston rod to aid the assembly's retraction in single-acting pneumatic systems. Compressed air enters across one of the cylindrical lids and fills just one end of the chamber. As a result, the piston and rod combination moves linearly and expands in a single direction while the spring is squeezed or stretched. The rod, piston assembly, and spring restore their initial positions as soon as the piston rod has exerted its greatest thrust. Air is released through a vent valve on one side of the caps. If a pressure drop or power outage occurs, the piston will return to its starting position. A push-type or pull-type cylinder can be used in a single-acting cylinder. In the push-type cylinder, the pressured air forces a piston rod out of a cylinder. The piston rod within a pull-type cylinder is pulled by the pressured air inside a cylinder (in-stroke or retraction).

Rodless Pneumatic Cylinders

The piston of a rodless pneumatic cylinder is propelled by compressed air to shift loads. The load is fixed on a carrier to which the piston is fastened. The carrier is moved straight ahead by the piston. The piston always moves in the motion of the part of a chamber that has the lowest internal pressure. Rodless pneumatic cylinders provide strokes at higher speeds similar to their assembly size. Hence, they are useful if the entire length must be decreased due to restricted space. End cushioning is required to avoid harsh contact on the piston following full-length passage at the end caps. An applied load or gravity carries out the retraction mechanism in less frequent varieties of single-acting cylinders. Single-acting cylinders are easy to build and economical because they use less air. They are perfect for punching, clamping, and positioning that need force delivery in one direction. Pumps and rams also contain them. The opposing spring force, however, limits the output force. The spring's size constrains the stroke length. With repeated use of the spring, piston strokes become erratic.

Applications for Pneumatic Air Cylinders

Air cylinders are used to close, open, and hold or release many systems and materials. They are most frequently employed to support pneumatic systems. Pneumatic cylinders serve varied purposes in the automotive sector. They are utilized for suspension and braking in cars and trucks.

Choosing the Right Pneumatic Cylinder Supplier

To make sure you have the most constructive outcome when purchasing Pneumatic Cylinders from a Pneumatic Cylinder Supplier, it is important to compare at least 4 Manufacturers using our Pneumatic Cylinder directory. Each Pneumatic Cylinder Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Pneumatic Cylinder business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Pneumatic Cylinder companies with the same quote.

Air Cylinders

Air Cylinders Assembly Machinery

Assembly Machinery Ball Bearings

Ball Bearings Electric Motors

Electric Motors Fractional Horsepower Motors

Fractional Horsepower Motors Friction Materials

Friction Materials Linear Actuators

Linear Actuators Linear Bearings

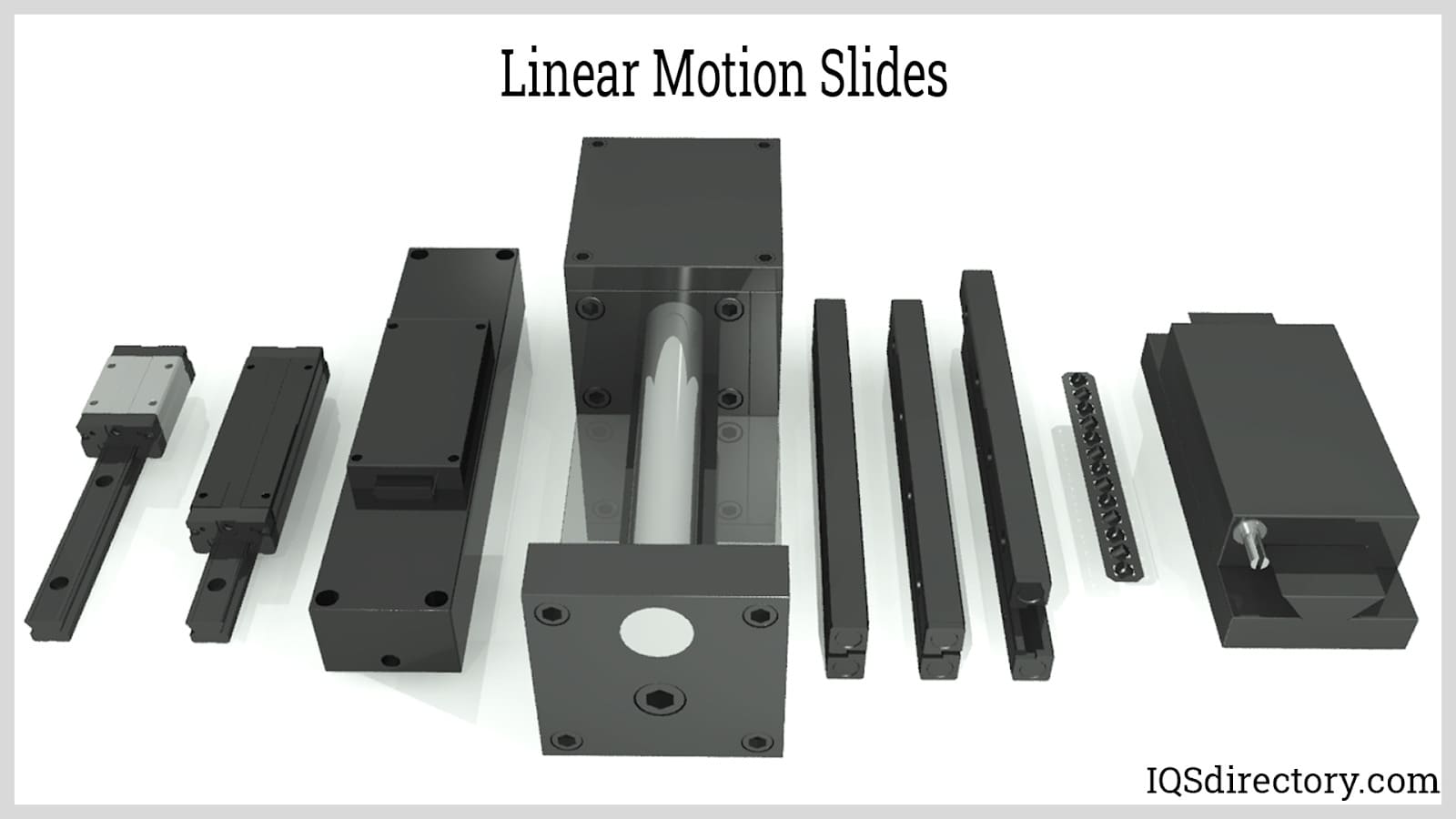

Linear Bearings Linear Slides

Linear Slides Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services